Benefits at a glance

Easy to process, no need for dismantling

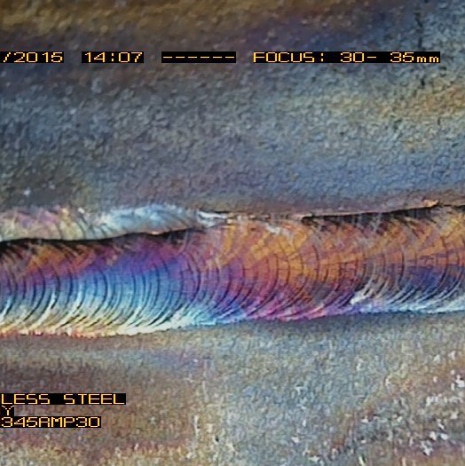

High quality image for very detailed inspections

Very robust for repeated inspections

Customer needs

Regular weld inspection in power plants is crucial for several reasons, primarily related to ensuring the safety, reliability and efficiency of the plants operations.

- Dealing with high temperature, pressure and potentially hazardous substances, weld failures in power plants can lead to leaks which may result in accidents, fires or explosions. Regular inspection allows for the detection of flows before they lead to catastrophic failures preventing downtime, equipment damage and potential environment or safety incidents.

- Welding inspections at power generation plants also ensure compliance with the strict regulations and industrial standards to which they are subject.

- Regular weld remote visual inspection contributes to weld’s integrity and so to overall asset integrity as long-term investments.

- Identifying areas for improvement in welding processes, materials or techniques while regular weld inspections may lead to optimize performance, enhance efficiency and extend the lifespan of critical components.

- Early detection of welding issues can help in addressing problems before they escalate and so lead to cost savings by avoiding expensive repairs, minimizing downtime and preventing the need for premature component replacements.

Power plants have so many reasons to schedule regular welding inspections, especially for critical internal pipe networks. In our example, a major energy utility player is required to control every 2 years welds of a critical internal pipe network. The pipes are 150 mm diameter and up to 20 meters long with several bends. The operator needs to access all welds and control corrosion and cracks taking up a few challenges:

- all welds need to be accessed and surveyed, but there is no intermediate borehole

- all welds need to be consistently and repeatedly controlled, so comparisons can be established from one inspection to the other

- the operation has to be done under time constraints

The solution : Visioprobe remote inspection camera

Remote visual inspection weld camera can navigate in confined spaces without requiring dismantling. It is a non destructive method. Remote visual inspection is therefore ideal for minimizing costly downtime to equipment or processes. What’s more, the video recordings from this rvi inspection are of the highest quality for accurate analysis, and can be used for documentation, training or decision-making.

Detailed solution:

- Visioprobe Pan&Tilt 45 mm weld camera with Focus

- Visioprobe control unit

- 30 m reel with push rod

- 100 mm centering device

After cleaning the area to be inspected and so clear of any coatings or dirt that could hinder the inspection to obtain a clear image of the weld, the weld inspection camera, centered in the pipe, is pushed with a flexible rod for a swift access to all welds. Once positioned close to the weld to be inspected, the camera then tilts in order to have a direct view to the weld bead and rotates to perform an orbital 360° inspection of the weld. Real-time images are transmitted to the control unit where the operator is reviewing them, looking for potential defects such as cracks, porosities, inclusions, poorly executed welds or any other issues that could compromise the weld’s integrity. A video is recorded, with the number and position of the weld and pictures are taken for all points of interest. Photos, videos and notes are then generated into a report to record the conditions of the weld and any identified defects.

The complete pipe is inspected within half a day with all welds checked in full. Where a videoscope would not allow for access and consistent orbital inspection, Visioprobe allows for a swift, consistent and repeatable remote visual inspection. The corresponding equipment is then referenced at client’s end and is used for each inspection, whether by internal or external staff. Visioprobe is a perfect solution for remote visual inspection of all welds, especially in critical assets such as power plants.