Benefits at a glance

No personnel exposition to potential dangers

Range of cameras addressing all volumes and types of applications – Wide range of mobility solutions to adapt the solution to the asset

Easy management of photos/vidéos and generation of personalized inspection report in a few clicks

Customer needs

Many industries have to inspect pipes regularly for crucial reasons such as safety, regulatory compliance, leaks prevention, process efficiency, contamination prevention or equipment lifespan.

Regular remote visual inspection will prevent any defect in pipes avoiding accidents, fires or environmental contamination with associated serious consequences as well as prevent costly and potentially dangerous pipe failures or process efficiency reduction.

Timely maintenance and regular rvi inspection will also maintain compliance in industries that are subject to regulations and standards as well as extend the lifespan of pipes reducing the need for costly replacements.

In the oil & gas industry, pipe inspection is critical as defects can lead to environmental disasters posing significant safety risks.

In power generation industries, pipelines need to be reliable for the transportation of steam, water and other fluids. In chemical or food processing industries, pipelines need to be reliable for the transportation of a variety of products. Remote visual inspection of those pipelines will maintain the quality and safety of the different processes. Pipe inspections in large construction projects such as bridges, tunnels and buildings are necessary to guarantee the structural integrity. Extensively used in municipal utilities, such as gas distribution, water supply, and sewage systems, pipe inspection is critical in order to maintain these essential services.

More broadly, monitoring the condition of pipes is a fundamental aspect of asset management. It helps industries track the health of the infrastructure and plan for maintenance or replacement when necessary. But inspecting pipes in industrial settings presents several challenges. Pipes can be located in hard-to-reach or confined spaces; making it difficult for inspectors to access and perform thorough inspections. Ensuring the safety of inspectors is a paramount concern. Inspecting them can be hazardous due to the presence of potentially harmful substances, extreme temperatures or confined spaces. Finally, pipes can have complex shapes and connections, making inspections more difficult.

Industry must therefore choose the right remote visual inspection equipment to inspect pipes addressing all challenges.

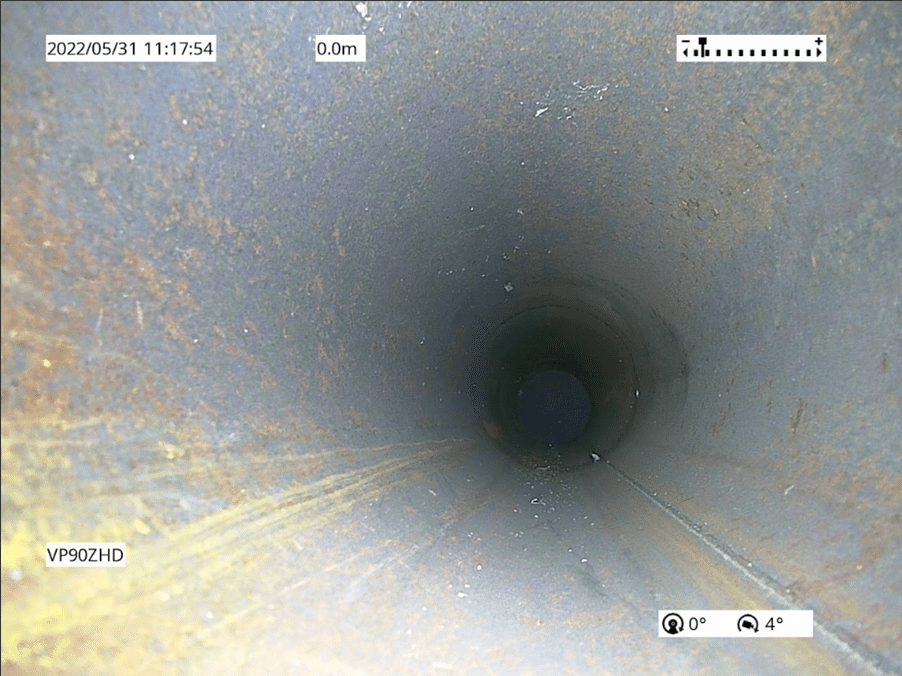

The solution : Visioprobe pipe inspection camera

Designed to meet all industrial needs, the Visioprobe remote visual inspection equipment has 3 compact remote inspection cameras for all volumes and types of visual inspection applications. The wide range of centering devices optimizes camera alignment inside the pipe, making it easier to navigate through pipe bends, elbows and forks, while reducing the risk of damage. Finally, the ultra light and easy control unit completes the solution for fast and efficient inspections.

Specifically for pipe inspections, the industry will choose its camera according to the various shape elements of the pipe to be inspected: the diameter of the entry point or the pipe elbows to be passed inside the pipe as well as the length to be covered for inspection. The most common configuration for pipe inspection combines the control unit with a pan & tilt 45mm diameter camera with focus, 30m of reel with push rods and a centering device according to pipe width.

/// Pan & Tilt 45mm camera with focus

/// Control Unit

/// 30m reel with push rods

/// On demand range of centering devices

Before inspecting the pipe, the operator must first ensure that the area is safe for inspection. This may include lockout, draining or cleaning procedures, personal protective equipment (PPE) and safety barriers. When the equipment is isolated and secure, the operator inserts the pipe inspection camera inserted in the centering device inside the pipe through the appropriate entry point. Visualizing the real time images on the control unit, he uses the camera’s controls to navigate through the pipe adjusting camera’s orientation, zooming in and out and panning to thoroughly examine all areas and detect issues like corrosion, leaks or blockages. The operator documents its findings as he goes along including photos and videos which he can annotate. Once inspection is complete, post-processing brings the operator to review the collected data and assess the condition of the pipe. To finish, he generates a detailed report summarizing the inspection findings to help global decisions about maintenance and repairs.

Remote visual pipe inspection cameras allow inspections to be conducted without exposing personnel to potential dangers, such as high temperature, confined spaces or chemical hazards. They navigate tight spaces without the need for shutdowns, minimizing downtime and operational disruptions offering long term cost savings. Non destructive they are able to cover a large area in a relatively short amount of time.

Visioprobe is a perfect tool to perform the regular pipe inspections in all industries. Coming as a range, the remote visual inspection equipment offers various diameters and configurations to accommodate all pipeline inspections.