Visioprobe solution for remote visual inspection

A complete range of inspection cameras designed to meet your needs

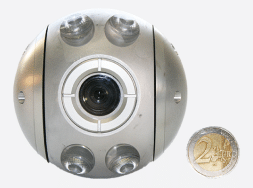

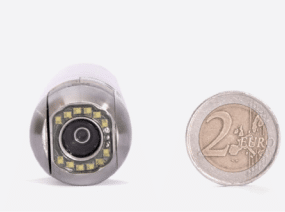

Visioprobe solution offers a robust range of pan tilt cameras for visual inspection. 90mm, 45mm or 28mm diameter, the 3 compact cameras cover all volumes and types of visual inspection inspection applications. Pan&Tilt, easy handling, waterproof and rugged, Visioprobe cameras stand the test of time.

Ultra light and easy to use control unit

Touch screen, user-friendly, everything at your finger tips. Visual inspection made easy.

Whether you want to take photos or record video (or both at the same time), include text, or navigate in the library, everything is at your fingertips. There is no confusion possible. Inspection cameras are controlled with a joystick for intuitive and precise movements. Share your work with colleagues in realtime or once the inspection is over using the video or the USB port.

control unit with

touch screen and

simple menus

control unit with

touch screen and

simple menus

- 7″ LCD touch screen

- Ultra resistant polycarbonate body

- Compact, Ergonomic, Robust

- 4 hours autonomy and easy interchangeable battery

- Automated report edition

- Photo and video recording on USB stick – jpeg/mpeg4 format

- BNC PAL video output

- Neck belt, anti-glare sun shade

Visioprobe control unit offers an ergonomic control interface allowing for easy management of photos/videos and generation of personalized inspection reports in a few clicks. Its intuitive power variation joystick provides precise control of cameras and its interchangeables batteries with 4 hour of autonomy handle even the longest inspections. A video output and USB port make possible data sharing and collaborative work. Visioprobe control unit is a scalable solution designed to accommodate future camera developments and accompany your inspections over the long term.

More than just a product, you need service

Our promess is simple : our standard products are always available on the shelf, and repair (if it happens) is turned around rapidly with limited cost. Gain time and make money with VISIOPROBE : reduced delivery time, increased availability and total cost under control.

Inspection camera business cases

FAQ ABOUT VISIOPROBE’S INSPECTION CAMERA

What are the standard use cases for inspection cameras?

A remote inspection camera can be used in various industries for tasks such as quality control, maintenance and safety inspections. It allows the operator to remotely inspect and assess the condition of hard-to-reach or hazardous areas, providing real-time visual information.

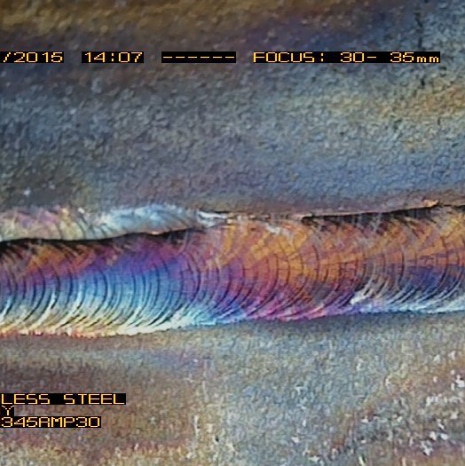

- Remote inspection cameras may inspect and assess the quality of manufactured products such as welds, coatings and surface finishings.

- In the aerospace industry, a small inspection camera may be used to inspect aircraft components, engines and airframes to detect defects, wear and tear or structural issues in a non-invasive manner.

- In the automotive industry, they inspect parts, welds and assemblies as engines, chassis and critical components.

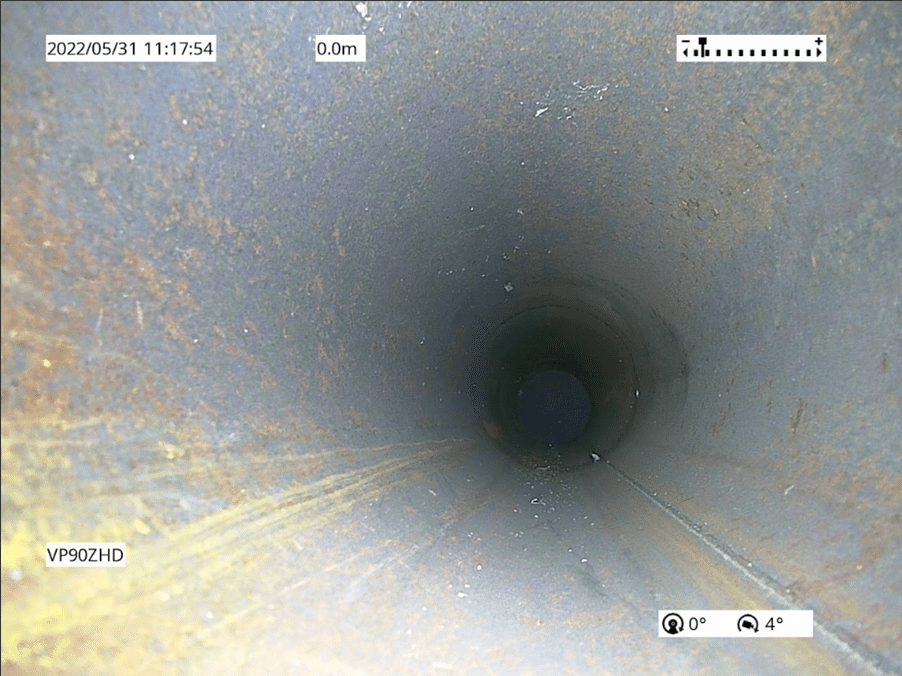

- In the petrochemical and refining industry, small inspection camera with light is used for the inspection of pipelines, pressure vessels and storage tanks to identify corrosion, cracks and other defects that could lead to leaks or accidents.

- In power plants, it is used to inspect equipment such as boilers, turbines and heat exchangers to ensure the proper functioning and safety of these critical systems.

- In oil and gas industry, inspection cameras are used to inspect oil wells, drilling equipment and pipelines for integrity and safety.

- Remote visual inspection cameras are also used to inspect the condition of bridges, tunnels and building structures to identify structural issues, corrosion and other potential hazards.

- In pharmaceuticals and food production, they inspect equipment, pipes and vessels for cleanliness and product quality to ensure compliance with industry regulations.

- In civil engineering industry, they inspect sewage and water systems, storm drains and environmental structures to identify blockages, leaks and structural issues.

Inspection cameras: what, where, when?

Inspection cameras are part of the Remote Visual Inspection (RVI) range of products.

One set of inspection camera usually includes the following pieces of equipment :

- Control unit with live video monitoring, as well as various functionalities : video recording, text overlay, camera control :(pan, tilt, focus, light)

- Camera head : from 20 mm to 200 mm. The camera head can be forward view only (smaller diameters) or pan & tilt (from 28 mm onwards). Lighting is provided by LEDs mounted on the camera head.

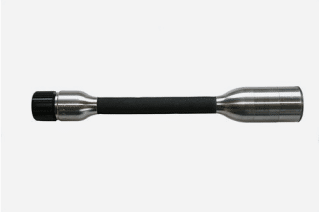

- The camera head is being moved through various systems : flexible cable, push rod, telescopic pole, crawler. Its maximum range is linked to the system used but can reach up to several hundred meters with crawlers.

- Some accessories usually complete the system to improve ergonomics and performance : centering devices to have the camera in the center of the pipe for orbital weld inspection, measurement systems via laser, additional lighting.

The traditional markets for inspection cameras are the sewer, drilling and chimney markets.

- The sewer market needs relatively big size pan tilt camera combined with heavy weight long distance crawlers in order to progress through sewer pipes. Generation of inspection reports according to European standards is also required.

- The drilling market requires vertical long distance systems with strong waterproofness (up to 100 bars). Laser solutions are often embedded in the camera for telemetry.

- Chimney market is driven by costs and the cameras tend to be lower quality and robustness.

There’s in fact very limited offer as far as industrial markets are concerned. The applications in those markets are very different from one another and inspection cameras have often been developed on demand. Videoscopes tend to fill this offer gap even though they are not always fully fitted to the application.

Smaller size, focus from contact to infinity, specific lighting and modular moving systems are some of the key requirements for industrial markets.

Why use a small pan tilt camera with light rather than a videoscope?

Inspection cameras and videoscopes are both latest generation equipments with a camera sensor on board. Though they could be named one for the other, they are usually differentiated based on the following :

- Size : videoscopes are below 12mm diameter and inspection cameras usually above 20 mm diameter.

- Articulation / rotation : videoscopes tips move through mechanical articulation systems triggered from the main control unit whereas inspection cameras heads embed pan and tilt motors.

- Modularity : videoscopes heads or tips are built in a scope or probe with a defined length (2 meters, 3 meters, …) which can not be changed. Inspection camera heads are linked to the cable, push rod or crawler through connectors and can move from one system to the other. Their potential application scope is therefore higher.

Other differences include lighting power, optics and maintenance :

- Lighting power can be higher with inspection cameras due to the diameter of the head; multiple LEDs (6, 12 or 24) are positioned at the tip of the head and bring strong lighting. LEDs can also be positioned in order to prevent overexposure. On the other hand, videoscope light sources are included in the control unit. Their power has to be limited due to space and overheating. The light is brought through fiber optics to the tip of the videoscope.

- As far as optics are concerned, videoscopes usually work with interchangeable tips in order to manage various fields of views, focus ranges hence working distances. Industrial inspection cameras can include a variable focus system allowing them to work at any distance for a given field of view.

- Finally, maintenance is the last but strong differentiating point between pan tilt inspection cameras and videoscopes. Videoscopes are highly complex systems with articulation mechanics, optics, sensors and electronics all tied into 4, 6 or 8mm diameter. The tip of a videoscope represents up to 70% of its value. It’s however its most exposed and difficult to maintain part. On the contrary, pan tilt visual inspection cameras are robust, with all sensitive elements protected by aluminum or stainless steel outer shell, and modular, with service performed element per element (sensor, motors, optics), driving maintenance costs down in a dramatic way.

Videoscopes and inspection cameras are two complementary tools. Videoscope’s unbeatable advantage is its diameter allowing for insertion into the smallest environments. However, inspection cameras should take over as soon as the insertion diameter is big enough. Modularity brings better access, focus means easier inspection and stronger lighting guarantees a better image.

What is the right Visioprobe configuration for me?

To select the right Visioprobe inspection camera solution, you first have to identify your inspection objectives. Clearly define what you have to inspect: pipelines, machinery…? You also need to consider the environmental conditions in which the inspection camera will be used by considering factors such as temperature, humidity, or the presence of dust or chemicals and to define your access points considering the size and shape of the spaces you’ll be inspecting.

Visioprobe solution offers a full range of inspection cameras which offer different specifications to address the widest possible field of application: 3 different sizes associated with different features such as light, camera material, image quality and resolution, manual focus or zoom…To optimize your results, a full range of mobility accessories is also available to adapt the camera specifically to the environment. Flexible cables, push rods on reels or poles enable you to access any type of confined space. Custom-made centering devices ensure correct positioning, resulting in high-quality images, reduced vibration and camera protection. Finally, suitcases or backpacks make it easy to transport your visual inspection system. By carefully considering these factors, you can tailor your inspection camera configuration to the specific needs of your industry, ensuring efficient and effective inspections. Foretec visual inspection experts are at your disposal to suggest the best configuration according to your objectives.

Why use a pole camera for remote visual inspection?

Pole camera, also known as inspection camera or telescopic camera are valuable tools for remote visual inspection in various applications. A pole camera associated with telescopic pole allows the inspector to access and view areas that are otherwise difficult to reach as confined spaces, elevated locations, tight crevices, and areas with limited access, where traditional inspection methods might be impractical or unsafe. A pole camera offers a safe, efficient, and cost-effective means of conducting remote visual inspections. Their adaptability and ability to provide real-time data make them an invaluable tool for ensuring safety, quality, and compliance in a variety of applications.

How much does it cost?

Visioprobe cost depends of the configuration you will choose to address your need. Feel free to contact your local reseller or to contact us directly to ask for a quote.

Where is Visioprobe manufactured ?

Backed by its experience in remote visual inspection, Foretec has designed and developed its own solution named Visioprobe. Based in France, Foretec manufactures and mounts the Visioprobe solution in its headquarter, in France. Visioprobe is 100% french.

Where can I buy Visioprobe ?

You can buy Visioprobe everywhere. Our distribution network or our export sales force will handle your request.

Is it possible to have a demo?

No matter where you are, you can ask for a demonstration. We’ll do our utmost to arrange it with our local dealer or directly with you.

Can I use Visioprobe under all conditions?

Remote visual inspection cameras can be used in various industries for visual assessments of hard-to-reach or inaccessible areas. If known as a versatile tool, the effectiveness of an inspection camera can be influenced by factors such as environment, type of inspection, and specific features of the camera. With the support of one of our visual inspection experts, you’ll acquire the perfect solution for all your inspections.

Who is Foretec?

Foretec is a recognized supplier of visual inspection solutions in France. Drawing on its experience, Foretec has developed its own visual inspection solution.

What are the main client references?

Our products are used in the main industries like nuclear, and power generation, oil & gas industry, pharmaceutical industry, global industry or security. Some of our major customers include TotalEnergies, EDF, Sanofi, Safran, Naval Groupe, Vinci, Orano, Apave, Airbus, Alstom…

What is average cost and turnaround time for repairs?

Unlike video endoscopes, which can sometimes involve high repair costs, Visioprobe’s after-sales service is low-cost. Repairs are generally carried out within 3 days.

What are quality standards?

Foretec, Visioprobe’s manufacturer is ISO 9001 certified. Foretec is so committed to maintaining a high standard of quality and customers can expect consistent quality with Visioprobe products. ISO 9001 is an internationally recognized standard. Worldwide customers can be assured that our company’s quality management system aligns with global best practices, providing a common understanding of quality expectations.

How do a remote inspection camera can play a significant role in enhancing safety in industrial settings?

A remote inspection camera can play a significant role in enhancing safety in industrial settings in several ways. A remote inspection camera can reduce human exposure to hazardous environments enabling workers to assess potentially dangerous or inaccessible areas without physically entering them. It also minimizes the risk of accidents by providing real time visuals and data from remote locations abling to identify potential safety hazards or equipment malfunctions. Using a remote inspection camera in industrial settings also improve inspection efficiency allowing for quicker and more efficient inspections.